I. Gate opening (wire magnetic encoder) displacement sensor overview:

1. Gate opening (pull magnetic encoder) displacement sensor, also known as pull rope encoder, pull rope ruler, pull wire ruler, pull wire encoder, pull rope displacement sensor, the sensor adopts the multi-loop magnetic induction absolute encoder independently developed by Miran company, the internal use of high-strength potion-sealing adhesive package (limited protection level IP68), Thus, the magnetic induction absolute alignment encoder can work normally under water for a long time.

2. Gate opening (magnetic encoder) displacement sensor in the structure of the exquisite integration, fully combined with the advantages of Angle sensor and linear displacement sensor, to become a long measurement stroke, simple installation, with high precision measurement of the absolute value of the pull wire displacement sensor.

II. Gate opening (pull wire magnetic encoder) Displacement sensor Technical parameters:

Project Specifications | Details | Remark |

Effective length | 100mm-4000mm | ZM |

Power supply | DC12V~DC24V (Voltage/current/RS485) | Fluctuation below 5% |

Power supply voltage VCC consumption current | 40mA | no mutation |

Signal output

| Voltage:0-5V,0-10V,

Current:4-20mA, Digital:RS485,SSI, Pulse signal:A/B/Z | Absolute position output type |

Linear accuracy | ±0.25%FS | |

repeatability | ±0.05%FS | |

Resolution | Analog output 16 bits, digital output 12 bits | |

Lightning protection/surge protection | Yes (GB/T 17626.5-2019) | |

Anti-static | Yes (GB/T 17626.2) | |

Corrosion protection | Salt spray test 24H, level 6 | |

Vibration resistance | 10Hz to 2000Hz,5g | |

Wire diameter specification | 1.5mm(SUS316) | |

Working temperature | -10℃~60℃ | At low temperature, no crystallization must be maintained |

IP | IP68 | |

III.Gate opening (pull magnetic encoder) displacement sensor wiring method (specific physical wiring shall prevail) :

| Current | Voltage | RS485 |

Red wire | DC12V~DC24V | DC12V~DC24V | DC12V~DC24V |

Black wire | 0V | 0V | 0V |

Green Wire | Output 4-20mA | Output 0-5V.0-10V | RS485 A+ |

White wire | None | None | RS485 B- |

Shield Ground | GND | GND | GND |

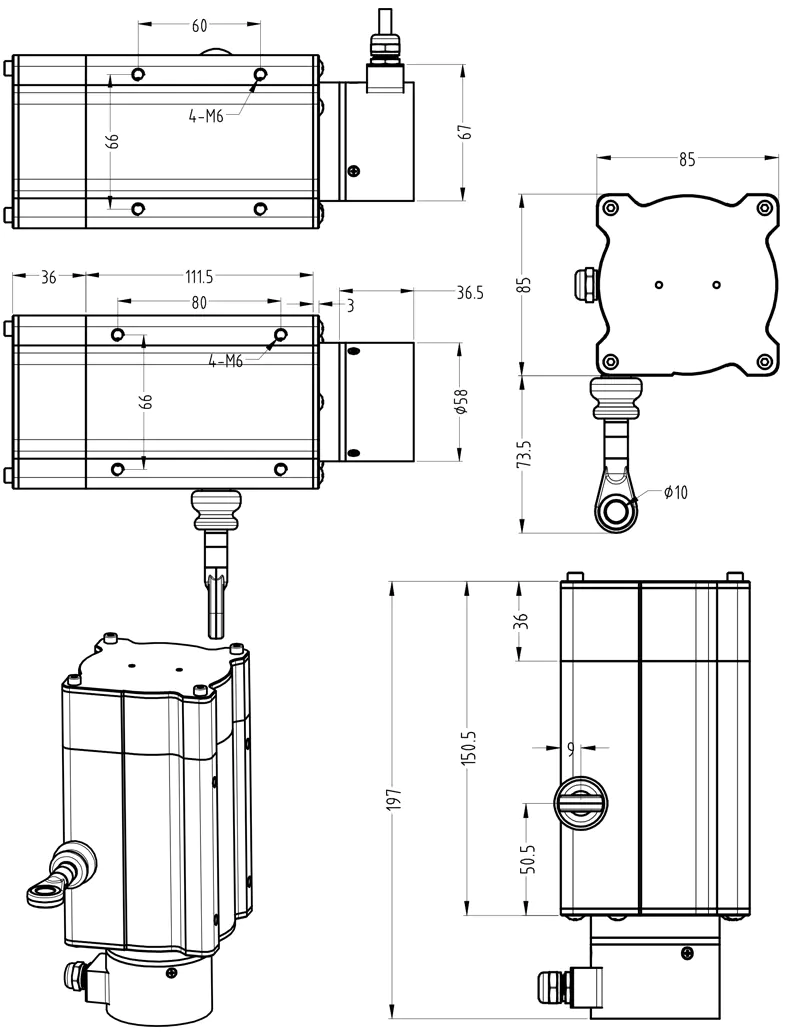

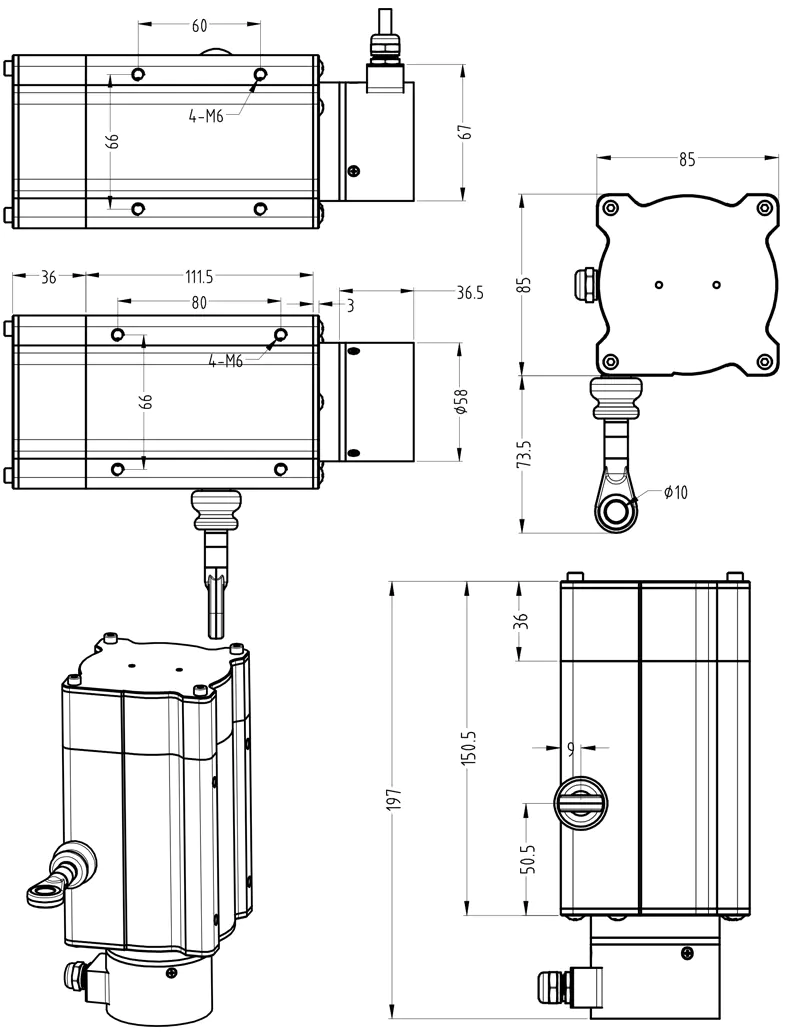

IV、Gate opening (cable magnetic encoder) Displacement sensor Installation size:

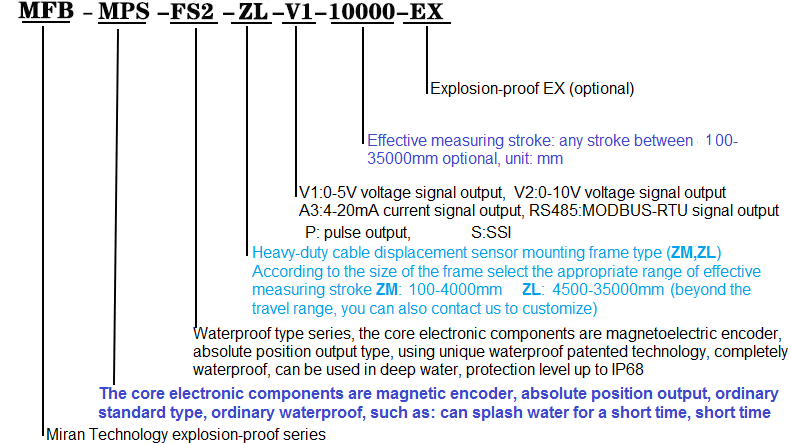

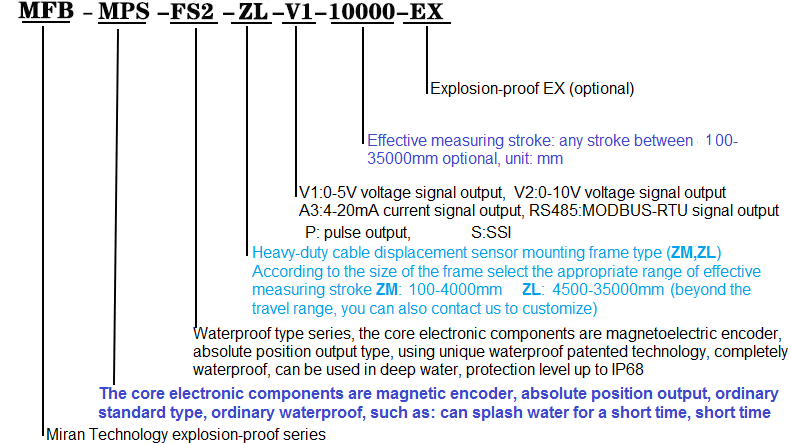

V.Gate opening (pull magnetic encoder) displacement sensor selection guide:

VI. Matters need attention:

1. The use of the bottom 6 (any three sides, pulling head surface can not be fixed) to fix the screw hole, according to the site and machine installation space facilities need, direct installation or additional protection or other mechanical use.

2. Stainless steel cable installation, must pay attention to the horizontal Angle, that is, as far as possible to make the cable from the outlet to the moving part of the mechanism, the horizontal slide during work.

3.Keep a small Angle (allowable deviation +/-3°) to ensure measurement accuracy and cable life.

The steel cable body is stainless steel and coated with fluorine layer, do not let it be hurt by external forces, burn, impact and other improper things: excessive dust, debris accumulation or enough to damage the steel cable stored in the internal pulley or wire outlet will cause damage to the steel cable, resulting in failure of operation.

4. Not installed in the workbench or fixed sitting, do not use hands or other products to pull out the steel cable and let it bounce back instantaneously. This will cause the cable to break and damage the body structure.

5. If used in the non-linear movement of the mechanism, please install the appropriate pulley operation.

6.If used in bad environment or special occasions, please install your own protection mechanism

VII. Application Fields

Crack measurement and monitoring, bridge measurement and monitoring, storage location, reservoir dam protection, gate opening control, pressure machinery, paper making machinery, textile machinery, sheet metal machinery, packaging machinery, printing machinery, level control instrument, construction machinery, industrial robot, injection machine, woodworking machinery, elevator, air compressor/hydraulic press, height machine, X-Y axis and other length displacement, liquid level and other related dimensional measurement and position control.